──Jun 21, 2019QLQ Chemicals for Shiny Gun Color in Zipper Plating

1. Zipper Plating is a very common and widely used process for making any zipper look fantastic and colorful. We can plate it zipper in two ways. 1. Electroplate Way we also call it Hot Plating and 2. Manually or Machine Plating we also call It Cool Plating (Also known as Dipping Way) in this article we will discuss about how to make Shiny Gun Color using Dipping Way.

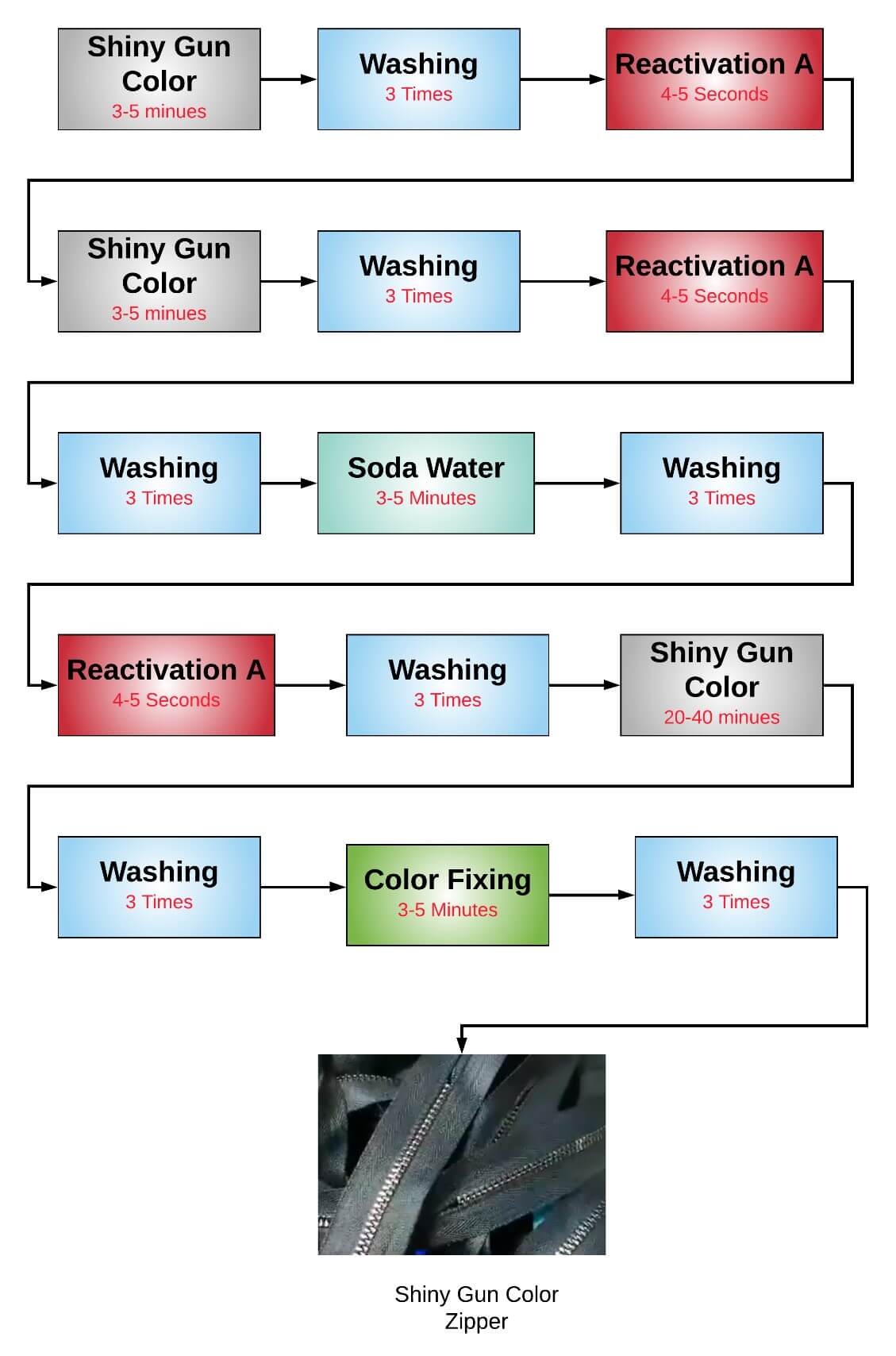

The Process

Process Short Forms

Some of the important processes with descriptions

Machines Needed:

QLQ-CCPMD Automatic Metal Zipper Chemical Cold Plating Machine(with two chemical tanks, have economic model & reinforced model for choosing)

Chemical Needed:

1. QLQ-30A

2. QLQ-30B

3. Water

4. Soda Water (Soda:60-80g, Water:3L)

5. Oil Remover (Washing powder:100g, Sodium Cyanide:6g, Water:3L)

Oil Remove

Duration: 2 minutes.

First, the Zipper goes through the Oil Cleaning or Oil Removing Process which removes oil from the teeth of the zippers, If the metal zipper is after shine coil plating then no need to remove oil from it. We will use the Oil Remover Solution for this. To making Oil Remover Solution we will need Washing powder:100grams. and Sodium Cyanide:6grams. for every 3L of water.

Dipping with Shiny Gun Chemical from QLQ

Duration: 20 Seconds

After Oil Degreasing Process, The Zipper will go through washing tank. Then we are ready for Dipping with Shiny Gun Chemical Tank. For This We will have to Mix our Shiny Gun Chemicals in a fixed ratio. The amount will be the following form:

Chemical Name Ratio

After the Shiny Gun Plating Process the Zippers will again go through cleaning tanks.

From there the zippers pass through one “Activator Tank” and two “Washing Tank”.

|

Chemical Tank where the chemicals are supplied. We can manually control the supply of the chemical from the control board. Using high pressure chemicals spraying system to prevent zipper concave point scratched and improve chemicals reaction effect to make more stable and bright color. Zippers are completely soaked in chemicals in the chemical tank, which improves reaction time and effect, saves chemicals cost and improves zipper quality. |

|

Flap wheels system makes chemicals have more complete and faster reaction. The plated color is more stable & brighter, wash more clean and lower cost.

Then the metal zippers are sent to “Color Fixing Tank” which makes the color shinier and more beautiful. From there it flows through three “Washing Tanks” which removes the chemicals from the zipper very well.

some cleaning or washing processes. When it comes out, the zipper sent to an “Oven Case” so that the plated nickel color can be more long-lasting. Now the zippers are ready to be shipped.